| Equivalent caracteristic | Carbon | Glass |

| Tg | 130°C | 130°C |

| Density | 1.60 g/cm3 | 2 g/cm3 |

| Flex modulus | 85 to 95 GPa | 50 GPa |

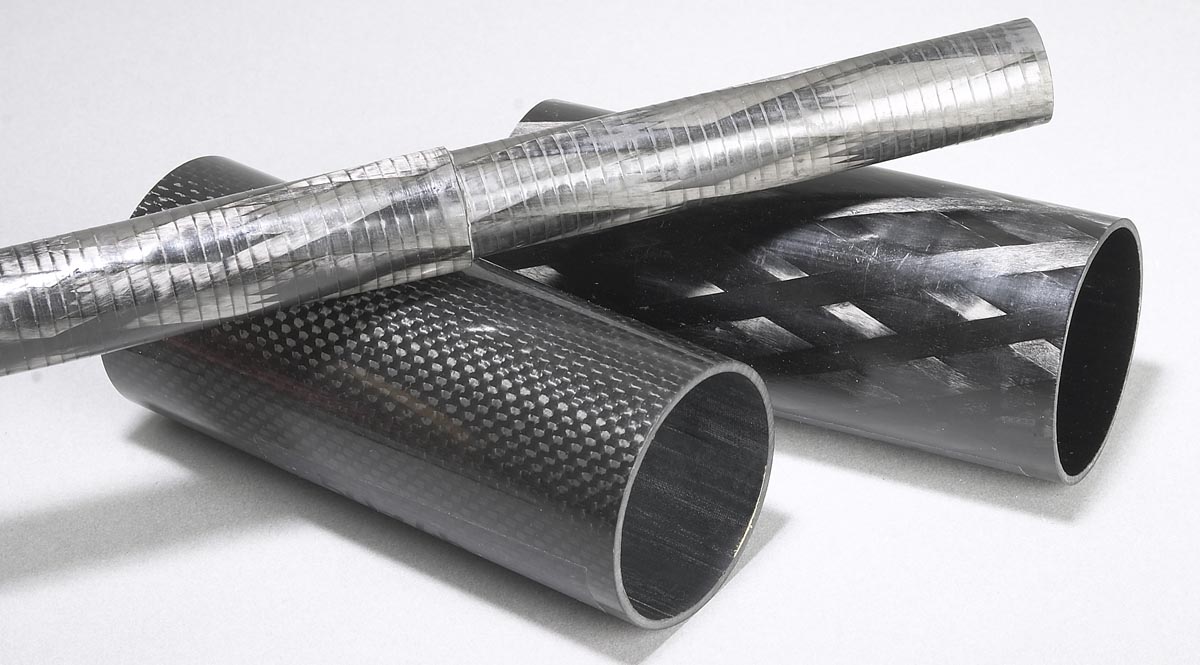

| Structure | Standard tubes : fiber 90° et 20° | Standard tubes : fiber 90° et 20° |

| Material | HR and HM Carbon | Glass E |

| Tolerance | +/-0.2 mm | +/-0.2 mm |

| Finish | Grip surface | Grip surface |

| Fiber | Carbon | Glass |

| Density | 1.60 g/cm3 | 2 g/cm3 |

| Flex modulus | 85 to 95 GPa | 74 GPa |

| Tensile strength | 4900 MPa | 2500 MPa |